Ever watched a metal project come together with clean, perfect cuts, and wondered what the secret ingredient was? Often, that secret isn’t just the saw; it’s the blade you choose. A dull or wrong blade can turn a quick job into a frustrating mess of sparks, rough edges, and wasted time. Choosing the right chop saw blade feels tricky, right? You face confusing terms like TCT, abrasive, and tooth count, and you worry about buying the wrong one for your metal or wood.

But getting the right blade makes all the difference. It means faster work, safer operation, and professional-looking results every single time. This guide cuts through the confusion. We will explain exactly what you need to know about chop saw blades—from materials to maintenance—so you can select your next blade with total confidence.

Top Chop Saw Blade Recommendations

- High performance aluminum oxide grain for long life and fast cutting

- High grain concentration for agressive cutting action and smoother running wheels

- Proprietary material mix ensures durable long life wheels

- High grain concentration for aggressive cutting action and smoother running wheels

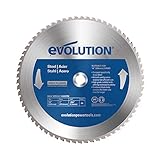

- 14BLADEST: 14 inch mild steel saw blade with 66 teeth for chop saws (*Designed to cut mild steel only, do not use this blade for galvanized, hardened, or high-carbon steel)

- MILD STEEL CUTTING BLADE: Evolution's unique blades are designed for cutting mild steel and ferrous metal - Made from high-quality Japanese carbide and heat-treated for added durability

- NO HEAT, NO BURRS & VIRTUALLY NO SPARKS: Our TCT blades allow you to touch the finished cut within moments of cutting, unlike other blades that make the material too hot to touch, Evolution blades produce virtually no sparks

- LONG BLADE LIFE: Premium Tungsten Carbide Teeth (TCT) ensure maximum longevity and durability, hardened steel body minimises vibration, thin kerf design for accurate cuts and extended tool life

- FULL RANGE OF BLADES AVAILABLE: Evolution Power Tools offers a range of specialist blades for cutting different materials: stainless steel, mild steel and thin steel, aluminum, wood, masonry and a multi-material cutting blade

- 14-Inch diameter by 1/8-Inch thick,1-Inch arbor Cut-off Wheel,10PCS

- Use on Stationary Chop Saws,Cuts Ferrous metals,Steel,angle iron,brass,bronze,carbon steel,and other metals

- High performance aluminum oxide grain for long life and fast cutting

- Leading Manufacturer Of High-Quality Products

- International Renown For Our Diverse Range Of Award-Winning Products

- Fully Equipped With State-Of-The-Art Technology

- All Products Have Been Designed With The Professional In Mind

- Constantly Modernizing Our Powerful Devices To Meet The Demands Of The Modern User

- Cermet II Teeth - Delivers up to 25X longer life, with high heat tolerance and increased hardness for superior wear and durability in metal cutting.

- Cooler & Faster Cuts - Up to 50X cooler and 10X faster cuts compared to standard grinding discs, reducing temperature and cutting time significantly.

- Triple Chip Grind - Produces precise, burr-free cuts with fewer sparks and reduced need for "hot" permits in metal cutting applications.

- Advanced Stabilizer Vents - Laser-cut vents trap noise and vibration, keeping the blade cool and providing straight, accurate cuts.

- Versatile Cutting - Ideal for cutting steel studs, angle iron, flat bar, EMT conduit, and more, making it a one-blade solution for metal cutting.

- Double reinforced for longer life, less burr and less vibration

- Up to 2 times the life of a 7/64" Thick abrasive wheel

- Up to 20% faster than a 7/64" Thick abrasive wheel

- Designed for cutting heavier gauge metal such as pipe or angle iron

- Special bond improves cutting speed and wheel life

- 14 Inch Metal Chop Cutting Saw Blade,Max RPM: 1800, 72 Teeth TCG, Kerf 0.095", Fine Finish blades produce extremely smooth chop cuts with 1-Inch Arbor

- Ideal For Studs & Tubing (Wall thickness 1/8" (11 gauge) min 1/2" max); Plates & Bars (Thickness 1/4" (11 gauge) min 1" max); RODS (Diameter 1/2" min 2" max) - Steel Studs, Angle Iron, Black Iron Pipe, Unistrut, Tubing, EMT Conduit, Flat Bar, All-Thread, Channel

- Compatible with 14" Evosaw 180HD 230, Evosaw 185 380 Chop Saws, Evolution S355MCS S355CPS S355CPSL S380CPS Metal Cutting Saws and all 14 Inch Saws

- Cermet Blend Teeth for cutting metal withstands impact, reduces wear, and lasts up to 3X longer than standard carbide and 25X longer versus standard grinding discs. these blades slice through the toughest of metals to produce precise, burr-free cuts with less sparks.

- Triple Chip Metal Cutting Grind designed to maximize life, speed, and maximum durability, optimized blade design reduces wandering and deflection of metal, creating precise cuts that require virtually no re-work

- 14" Abrasive Cut-Off Wheel

- Designed for cutting in ferrous metals

- 7/64" thick; 1" Arbor

- Premium design for faster cutting and longer life

- For use with 14" Cut-Off Saws

Choosing the Right Chop Saw Blade: Your Complete Buying Guide

A chop saw makes clean, straight cuts. The blade is the heart of this tool. Picking the right blade matters a lot. It affects how fast you cut and how good your cuts look. This guide helps you find the perfect blade for your needs.

1. Key Features to Look For

When you shop for a chop saw blade, look closely at these important parts.

- Blade Diameter: This must match your saw. Common sizes are 10-inch or 12-inch. Measure your current blade or check your saw’s manual.

- Arbor Hole Size: This is the center hole. It needs to fit snugly onto your saw’s spindle. Do not use a blade with a loose arbor hole; this is dangerous.

- Tooth Count (TPI): TPI stands for Teeth Per Inch. More teeth mean smoother cuts but slower cutting speed. Fewer teeth cut faster but leave a rougher edge.

- Kerf Width: This is how thick the blade is when it cuts. A thin kerf removes less material, making the saw easier to push through the wood.

2. Important Materials Matter

The material the blade teeth are made from determines how long the blade lasts and what it can cut.

For wood cutting, you will mostly see two main types of blades:

- High-Speed Steel (HSS): These blades cut wood well. They stay sharp longer than regular steel blades.

- Carbide-Tipped Blades: Carbide is much harder than steel. These blades last the longest and handle tough materials better. They are the best choice for frequent use or cutting harder woods.

If you cut metal, you need specialized abrasive discs or cold-cut saw blades, which use different materials designed to handle extreme heat and friction.

3. Factors That Improve or Reduce Quality

Blade quality directly impacts your safety and the finish of your work.

What Makes a Blade Better?

- Laser Cut Technology: High-quality blades often have laser-cut slots. These slots reduce vibration while you cut. Less vibration means a cleaner cut and a quieter saw.

- Anti-Vibration Features: Some blades have slots or special fillers in the body of the blade. These features absorb shaking, which keeps the blade straight and true during the cut.

- Tooth Geometry: The shape and angle of the teeth affect chip removal. Well-designed teeth slice through material efficiently.

What Lowers Blade Quality?

- Thin Body Construction: A very thin blade body can warp or wobble under heavy load. This wobble ruins the straightness of your cut.

- Poor Brazing: If the carbide tips are not strongly attached to the blade body, they can fly off during use. This is a major safety hazard.

- Cheap Steel: Low-quality steel dulls very quickly, forcing you to stop and sharpen or replace the blade often.

4. User Experience and Use Cases

Your project dictates the best blade choice. Think about what you cut most often.

For Fine Finish Work (Trim, Cabinets):

You need a high tooth count (60 to 80 teeth for a 10-inch blade). This provides a smooth edge that needs little sanding later. You sacrifice some speed for beauty.

For General Framing and Construction:

A medium tooth count (40 to 50 teeth) works perfectly. These blades balance speed and cut quality. They handle common dimensional lumber quickly.

For Ripping (Cutting with the Grain):

You want fewer teeth (24 to 30 teeth). These teeth act like small chisels, removing material fast when cutting along the grain line.

Always ensure your blade is rated for the maximum RPM (Revolutions Per Minute) of your specific chop saw. Using an under-rated blade can lead to blade failure.

Chop Saw Blade Buying Guide FAQ

Q: How often should I replace my chop saw blade?

A: Replace the blade when you notice it struggling to cut, making a lot of noise, or leaving rough, splintered edges. A dull blade makes your saw work harder.

Q: Can I use a metal cutting blade on wood?

A: No. Metal cutting blades or abrasive discs are not designed for wood. Wood blades are designed to clear sawdust; metal blades are not. Mixing them creates dangerous conditions.

Q: What does “Negative Hook Angle” mean?

A: This describes how the tooth is shaped. A negative hook angle is slightly angled backward. It reduces how aggressively the blade grabs the wood, which is great for preventing kickback when cutting plywood or laminate.

Q: Is a thicker blade always better?

A: Not necessarily. A thicker blade (heavy kerf) is very stable and resists bending. However, it creates more friction, meaning your saw has to work harder to push it through the material.

Q: What is the safest blade to buy for a beginner?

A: Look for a high-quality carbide-tipped blade with a medium tooth count (around 40T or 60T) and good anti-vibration slots. These offer a good mix of safety, durability, and performance.

Q: Do I need a different blade for plywood than for solid wood?

A: Yes. Plywood and melamine often chip easily. Use a blade with a higher tooth count (60T or more) and a negative hook angle to minimize tear-out on these delicate surfaces.

Q: What is the purpose of the slots on the blade body?

A: These slots are usually filled with a resin or copper material. Their main job is to reduce the heat and vibration generated while the saw is running. This keeps the cut smooth.

Q: Can I sharpen my carbide-tipped blades?

A: Yes, many professional shops can sharpen carbide tips. However, for common, inexpensive blades, replacement is usually easier and more cost-effective than professional sharpening.

Q: What is the most important safety rule when changing blades?

A: Always unplug the saw completely before touching the blade. Ensure the saw is off and the power cord is disconnected from the wall outlet.

Q: Does blade color mean anything?

A: Sometimes the coating color (like gold or blue) indicates a special coating that resists rust or reduces friction. It is a feature, but the tooth material and count are much more important.